DIAG264

Diag264 © 2021 by Rob Clarke is licensed

under CC BY-NC-ND 4.0

Important message

|

Dear Diag264

users,

I hope you

enjoy Diag264 and find it useful. Diag264 is now licensed under a Creative

Commons Attribution-NonCommercial-NoDerivatives 4.0 International License,

otherwise known as CC BY-NC-ND 4.0. This means it is free to download and

distribute the unmodified Diag264 software for personal use, but it must

include a link to the Diag264 website, and the license (Attribution). It is

not permitted to modify and then distribute the software (NoDerivatives), and

neither is it permitted to resell the software in any form (NonCommercial).

The reason

I've done this is to enable me to continue to provide free support to users

from code I know. Over the 10 years since I first released Diag264, I get 2

or 3 mails per month to the Diag264 email address asking for help with fixing

the issues and interpreting the results, which I'm always willing to do

within the constraints of my free time, plus it helps me improve future

releases.

Until now

I've never had any license restrictions, which has meant a number of

resellers have started selling it on Ebay or via their own web-shops. Some

have asked permission beforehand, but most didn't. In late 2020 I spent some

days trying to help someone with their C16 before we figured out that he was

using a version of Diag264 that had been modified and broken in the process. While

looking into this I then found another reseller had appeared on Ebay claiming

the work as his own and having removed my name. Hopefully you can all

understand how frustrating this is.

If you want

the software, you can download it and burn it to an EPROM/PROM yourself or,

if you don't have access to an EPROM burner, I will sell you pre-programmed

for cost of postage and the cost of the EPROM only. Please send me a message

you would like this.

I will allow

resale of the dongles and loop backs, as long as the attribution conditions

are met as described above.

If you did

purchase this software from another seller, I would encourage you to let me

know the details by emailing me at diag264@inchocks.co.uk, as

it’s against the terms of the license and discourages me from further

development and support of Diag264.

Regards, Rob

|

Introduction

DOWNLOAD

HERE!

This document describes operation of the Diag264 diagnostic

tool and harness. It can be used to assist in the identification of faults with

RAM, ROM, I/O & CPU ports, and TED registers. It has been tested on a wide

range of 264 series (aka TED) machines, including some non-standard

configurations and PAL and NTSC machines. This includes the C116, Commodore 16,

C232 and Plus/4, and even a V364!

Credits

It was developed primarily on a Windows 7 PC using TextPad, 64Tass,

YAPE and

VICE.

Thank you, in no particular order, to the following:

·

Bil Herd,

the lead engineer of the TED project, and who also wrote the TED

System Hardware Manual, Terry Ryan, Fred Bowen, John Cooper, Dave

Haynie, Bruce Ahearns, Dave DiOrio, Eric Yang, Bob Olah, Ted Lengthy and

countless other Commodore engineers who designed the chips and engineered the

TED system and to whoever in this list who wrote the 7360

Data Sheet !

·

Hársfalvi Levente (TLC) for thoughts on cold starting from

cartridges, joystick ports & TED latches

·

Martin Korth for the pagezero commodore specifications

·

Valentino Zenari (SVS) for the most excellent SVS ROM Map

·

Attila Grósz (Gaia) for the extremely cool YAPE

emulator.

·

Groepaz and the

Vice team for the equally cool VICE emulator and fixing the

bugs within days!

·

The Western Design Center for information on the 6551.

- Csaba Pankaczy (csabo) for info on which TED registers to

check.

- SukkoPera for the OpenC16Cart

project, saving countless original cartridges for their original purpose.

The HTML version of the

document can be found here and you can

contact me either by a private message to ‘crock’ on Plus4World or Lemon64.

You can also send email to a filtered email account at

Disclaimer

As soon as you undo the screws

and lift up the lid on an old 8-bit machine, there is an element of risk

involved. To use this diagnostic tool in its most effective form, it requires

replacing the kernel ROM in the machine and attaching loop-back connectors to

the interface ports. The TED chip especially is sensitive to abuse and the

built in latch register is easily broken by stray voltages and static.

Although I describe how to

build such connectors that I have successfully used myself, they are not

required to test the keyboard and joysticks if you don’t need to run the tests

unattended. Diag264 does provide features to manually test the keyboard and

joysticks and to bypass them to allow the rest of the tests to run unattended.

As keyboard and joystick problems are not usually intermittent in nature, this should

not be an issue for most users.

If you do choose to build loop-back

connectors for the keyboard or joysticks, I will provide any guidance that I

can, but please understand that you do so at your own risk.

Background

I acquired or built most of

Commodore's official diagnostic cartridges and harnesses for the 64, VIC-20 and

C128, which they sold to service centres, mainly to help me fix the growing

pile of computers I’d acquired. Fixing them became somewhat an obsessive-compulsive

habit, and I could not bear having broken machines lying around. In amongst

them I had a C16 and two Plus/4’s, only one of which worked. I started

searching around for a diagnostic cartridge for the 264 series but with no

luck. I knew Commodore had definitely made one, but I could not track it down. Finally,

I found an image of one on Plus4World, but as I never

got any response from the owner, I decided that my only choice was to build my

own.

Design and Theory of Operation

The design and operation of

Diag264 is closely modelled on the operation of the cartridges available for

the 64/128 and VIC-20. One of the aspects that I was most keen to copy was the

functionality of the Dead Test Cartridge of the 64. The primary use of this

cartridge was to find RAM issues in a machine that otherwise appeared dead.

The majority of Commodores

later 8-bit offerings used DRAM chips in either a 64k x 1 or 16k x 4

configuration. This usually meant that any dead RAM chip would make the machine

completely inoperable, as the zero page ($0002-$00FF) and stack ($0100-$01FF)

are rendered practically unusable. The kernal start-up routines in both the 64

and 264's make extensive use of the ZP and implicitly rely on the stack upon

the first execution of an RTS instruction. This presents a problem for any

normal cartridge based diagnostic tool because we are dependent on the kernal

to hand over control to the cartridge ROM.

The Dead Test cartridge avoids

this problem by making use of the 64's Ultimax mode, which was a legacy from

the MAX Machine, a cartridge only based console system which was a subset of

the later 64’s architecture. The Ultimax compatibility mode enables an external

cartridge ROM to replace the Kernal of the host machine and therefore bypass

the normal start-up routines, making it ideal for identifying RAM problems on

an otherwise ‘dead’ system.

The 264 architecture does not

include any way of auto-booting into an external ROM without trying to pull

some dirty tricks with the address lines, so it becomes a trade-off between the

conveniences of a cartridge versus the extra benefits of booting straight into

the diagnostic. The Diag264 ROM can therefore be compiled for either cartridge

or kernal.

The kernal option is a drop in

replacement of the kernal ROM, which is the 28-pin ROM chip with the identifier

beginning with 318004 (PAL) or 318005 (NTSC), which is in location U4 in a C16

and C116, and U24 in a Plus/4.

The cartridge, or low-ROM,

option involves either sacrificing a standard commercial Commodore C16/Plus

cartridge or, preferably, you can acquire a SukoPerra designed 264

cartridge blank from PCBWay.

The cartridge version is also known as the low-ROM option because it will work

in any of the available sockets which map to the low block of ROM from $8000 to

$C000. This means the low-ROM version will also work in the BASIC ROM socket

(U23 in a Plus/4, U3 in a C16/C116), and the low function ROM socket (U25 in a

Plus/4, not present in a C16/C116.)

If you choose to modify an existing

cartridge, you will need to remove the ‘low’ ROM and install a 28-pin DIL socket

in its place. With the edge connector facing towards you, this is the socket on

the left. The image in Figure 1, which is my own cartridge, also has a socket

in the ‘high’ ROM position, on the right. This is not required for Diag264.

Figure 1 - Cartridge Mod

The TED chip itself supports both NTSC and PAL standards, controlled

by bit 6 of register $FF07. The only differences between NTSC and PAL machines are

a different clock crystal and a slightly different kernal to correctly set the

state of the PAL/NTSC bit, and some other small modifications to take into

account timing differences.

When running from a cartridge or any of the low-ROM sockets, Diag264

queries the installed kernal to determine whether it should set NTSC or PAL

mode by checking the value of $F33F, which contains the default value for TED

register $FF07. The kernal version has no way to determine from software

whether the base machine is NTSC or PAL, so the ROM image is available in

versions which default to either NTSC or PAL. Nevertheless, for both the

cartridge and kernal options, it is possible to override the default by holding

down ‘P’ or ‘N’, as the machine is powered on, to force the software into PAL

or NTSC respectively.

Loop-back connectors

To determine the correct

operation of the various I/O interfaces, a number of loop-back connectors are

required. For a C16 or C116 you need a minimum of a serial port and cassette

connector. For a Plus/4 an additional user port loop-back is required to test

the Asynchronous Communications Interface Adapter (ACIA) interface and the 6529

8-bit port. The ACIA is a 6551/8551 chip which provides the RS232 support via

the user port.

It is also possible to

construct connectors for the joystick ports and keyboard, but this is not an

absolute requirement if the user is prepared to manually execute the keyboard and

joystick tests.

Cassette Connector

The cassette connector requires

a 7 pin mini-din connector, two 330 ohm resistors and a few short lengths of

wire. The diagram below is viewed looking at the rear/solder side of the plug.

|

Figure 2

- Cassette Connector

|

1.

GND

2.

+5v

3.

Motor

4.

Read

5.

Write

6.

Sense

7.

GND

|

The read line [4] is directly

connected to the write line [5] while the two resistors form a voltage divider

between the motor [3] and GND[7], with the resulting output being sufficient to

pull the sense [6] line high when the cassette motor is activated.

7 pin mini-din plugs can be

sourced from most electronics retailers such as Digikey or Mouser, and are

plentiful on Ebay. They can be rather tricky to solder given the small pitch of

the pins. It may be easier to find another lead with a 7-pin moulded plug

pre-attached if you happen to have one to hand.

Serial Connector

The serial connector is very

simple. As the data and clock lines are bi-directional, they are internally

looped back, the only exception being the ATN line. The connector consists of a

single link between the ATN [3] and Clock [4] line. The diagram below is viewed

looking at the rear/solder side of the plug.

|

Figure 3

- Serial Connector

|

1. N/C (Plus/4 & C232), +5v (C16 & C116)

2. GND

3. ATN

(Out)

4. Clock

(In/Out)

5. Data

(In/Out)

6. Reset

|

6 pin DIN plugs are in

plentiful supply and easy to solder as they usually have cups to hold the wire.

User Port Connector (plus/4 Only)

The User Port connector serves

two purposes, firstly to test the 8-bit 6529 port, and secondly the 6551/8551 ACIA

RS232 interface. This is constructed using a 24-way edge connector with .156”

spacing, the same as found on other Commodore 8 bit machines. The diagram below

is viewed from the rear of the plug. This connector can be acquired from the

sources mentioned above as well as from Jim Brain’s

go4retro store.

You need to make seven links,

four linking ports 0-3 on the 6529 to ports 4-7, which requires joining [B]

-> [6], [K] -> [7], [4] -> [J] and [5] -> [F] respectively. Then three

connections looping back the signals for the ACIA. These are [C] -> [M], [D]

-> [L] and [E] -> [H]. This implements a standard RS232 loop-back, the

only difference being that the plus/4 does not expose CTS on the user port.

Further detail about RS232 loop-backs can be found in the datasheet for the

equivalent W65C51N from the Western Design Center. (W65C51N

Datasheet)

Ensure that you clearly label

your connector ‘top’ and ‘bottom’ or preferably, insert the vertical keys

between 1 & 2 and A & B then 10 & 11 and L & M, as shown by

the blue dotted lines in the diagram. If you insert it upside down, you will short

the 9V AC to the 5V DC line and you will likely destroy something in your

machine.

Figure 4 - User Port Connector

|

1.

GND

2.

+5V

3.

/BRESET - Buffered Reset

4.

6529 – P2 (also Cassette Sense)

5.

6529 – P3

6.

6529 – P4

7.

6529 – P5

8.

RxC – Receive Clock

9.

ATN – IEC Attention

10. 9V

AC

11. 9V

AC

12. GND

|

A.

GND

B.

6529 – P0

C.

RxD – Receive Data

D.

RTS – Request to Send

E.

DTR – Data Terminal Ready

F.

6529 – P7

H.

DCD – Data Carrier Detect

J.

6529 – P6

K.

6529 – P1

L.

DSR – Data Set Ready

M. TxD

– Transmit Data

N.

GND

|

Table 1

- User Port Pin Description

Keyboard loop-back

There are two types of connector used on the 264 series. The

easy one is for the C16, which uses the same style keyboard connector as the

VIC-20/C64, albeit with a different layout, and uses a 20-pin SIL (single

in-line) plug with a 0.1” (2.54mm) pitch.

This plug can be built using a 40-pin IDE cable from a PC hard

drive which has the same 0.1” pitch. 80-pin IDE cables have each alternate

conductor grounded to reduce crosstalk but the wires are finer and difficult to

work with, so you’re better off avoiding them. Peter Schepers has some info on

preparing a similar plug for a Commodore 64 diagnostic harness here http://ist.uwaterloo.ca/~schepers/diagnostic.html.

The process is to split out the odd numbered wires and cut the rest back close

to the plug. Pin 1 is usually marked by a different colour.

The wires need to be connected as shown in Figure

5 and Table 2 - Keyboard Signals. Pins 2, 4, 5 & 20 of the keyboard

connector (not the IDE numbering) have no connection and pin 2 is used as a

key. I blocked off pin 2 with a pin from another header plug. As the other side

of the IDE cable has pin 20 blocked off, this makes it impossible to connect

the plug incorrectly. The contacts on a typical keyboard have around 110 ohms

of resistance, so I suggest putting small resistors in line to limit the

current. There is also a small signal diode with the cathode connected to the

keyport 6529 (Signal Out) side of the connector to prevent the joystick loop-back

interfering with the testing of the keyport.

Figure

5 - C16 Keyboard connector

The C116 and Plus/4 use an 18-way FFC (Flat Flexible Cable)

connector. Although the mechanical construction of the keyboard for the Plus/4

and C116 is quite different, it is electrically compatible, so you can use a

Plus/4 keyboard on a C116 and vice-versa.

This connector is not easy to construct unless you have a

supply of 18-way FFC cables. Some have had success using 0.1 inch pin headers,

but my concern with this approach is that the pins are much thicker than the

cable and it may stress the socket to the point where the original cable does

not make a good electrical connection. The other common issue is that as the

machines get older, the ends of the FFC cable have a habit of delaminating,

meaning the metal separates from the plastic making it a challenge to insert

the FFC into the socket. I would recommend that for casual use, the user just

stick with manual testing of the keyboard. The pins are in the same order but

numbered differently on the C116 and Plus/4, as seen in columns 6 and 7 of Table 2 - Keyboard Signals.

|

Signal Out

|

Signal In

|

Key

|

C16 Pin Out

|

C16 Pin In

|

Plus/4, C116 Pin Out

|

Plus/4, C116 Pin In

|

|

D0

|

K4

|

F1

|

19

|

7

|

18

|

6

|

|

|

D1

|

K5

|

S

|

8

|

9

|

7

|

8

|

|

|

D2

|

K6

|

T

|

12

|

10

|

11

|

9

|

|

|

D3

|

K7

|

V

|

11

|

3

|

10

|

2

|

|

|

D4

|

K0

|

9

|

13

|

18

|

12

|

17

|

|

|

D5

|

K1

|

P

|

1

|

15

|

1

|

14

|

|

|

D6

|

K2

|

;

|

16

|

14

|

15

|

13

|

|

|

D7

|

K3

|

2

|

6

|

17

|

5

|

16

|

|

Table

2 - Keyboard Signals

Joystick loop-back

The design of the joystick interface on the 264 series is

different to other 8-bit Commodore computers. With the exception of the fire

buttons, all the control lines from ports 1 and 2 are all wired together and

connected to the TED’s keyboard latch. Whereas the 64’s joystick interface

worked by pulling the control line to ground, this interface works by using a

buffered line of on the data-bus as the joysticks input. Joystick 1 uses D2, and

Joystick 2 uses D1.

I tried a few ways of building a test circuit that I felt was

safe for the TED, and the one shown in Figure 7 was the simplest that I was

comfortable using. A 74LS244 is perfect for our needs, it is a TTL octal buffer

with two active low enable lines, each enabling 4 outputs. By driving the

enable lines with the joystick select lines and holding the inputs low, it

effectively emulates the joystick being pushed in every direction at once. Again,

as the contacts in the +4 Joystick have a resistance of around 110 ohms, I have

included similar valued resistors in series with the outputs. The +5V and GND

are available on both ports and can be taken from either or both. Although you

can solder the wires to 8-pin mini-dins, it is very fiddly and I would suggest finding

and cutting a cable with a moulded plug, such as old AppleTalk network cables.

|

Figure 6

- Joystick Port Connections

|

Figure

7 - Joystick Test Circuit

|

Operation & Test Walkthrough

Install the ROM or insert the

cartridge, connect the loop-back connectors, connect a monitor or correctly

tuned TV and finally the PSU, then power on the machine. Most of the screen

shots that follow are either grabbed from YAPE or VICE simply because the

quality is better, but some of the ones that rely on the loop-backs are taken

with a camera pointing at my LCD TV.

Low Ram Test

The first sequence of tests is

run as soon as the CPU hands over execution to the diagnostic ROM. The

principle is to execute a memory test of the address space of $0002-$0FFF

without making any use of the Zero Page or Stack. This is complicated by the

restriction that we only have the A, X & Y registers available on the CPU

and you also need to have some means of communicating a meaningful status back

to the user in the case of finding a fault. The test routine achieves this by

using the stack pointer (SP) as a fourth register and the screen and border

colour to communicate the status.

First is a data-bus test which

writes a sequence of values to a fixed location, in this case $00FF. The values

test each data line in turn, using values 1,2,4,8 etc. Any failure to read back

the same value will either indicate a problem with the data line or with one of

the DRAMs. I say either because although these tests can give a strong indication

of where the problem may lie, it is frequently impossible to be definitive.

If a problem is detected, the

border will flash from 1 to 8 times, followed by a short pause. The number of

flashes indicates which data line is at fault. Additionally, the screen

background colour is set to red, so you can tell where in the test sequence the

problem was found.

The screen contents are a

useful source of information when diagnosing ram faults; it is possible to

identify stuck data lines or addressing faults just by looking at the screen

contents. For this reason, if the ram tests detect an error and drop into the

screen flash, the screen will alternately fill with ‘@’ symbols and ‘ ’,

which are values $00 and $FF respectively. It will also alternate from filling

top downwards and bottom upwards, to help identify addressing faults. The

patterns you should see are shown below in Screenshot 1 - Low RAM Flash Screens.

’,

which are values $00 and $FF respectively. It will also alternate from filling

top downwards and bottom upwards, to help identify addressing faults. The

patterns you should see are shown below in Screenshot 1 - Low RAM Flash Screens.

If you see the screen filling

with values other than with ‘@’ or ‘ ’, or the fill is not

uniform, this indicates a RAM problem and you may be able to determine the

problem by cross referencing the observed characters with Table 3. Note that

the CBM characters do not render correctly on the web page. As there would

be no point proceeding with any further tests if the zero page or stack is at

fault, the machine will continually repeat the flash cycle until powered off or

reset.

’, or the fill is not

uniform, this indicates a RAM problem and you may be able to determine the

problem by cross referencing the observed characters with Table 3. Note that

the CBM characters do not render correctly on the web page. As there would

be no point proceeding with any further tests if the zero page or stack is at

fault, the machine will continually repeat the flash cycle until powered off or

reset.

Screenshot

1 - Low RAM Flash Screens

Symptom

|

Cause

|

Symptom

|

Cause

|

Plus/4 IC

|

C16/C116 IC

|

|

A instead of @

|

D0 stuck high

|

instead of

|

D0 stuck low

|

U11

|

U5

|

|

B instead of @

|

D1 stuck high

|

instead of

|

D1 stuck low

|

U12

|

U5

|

|

D instead of @

|

D2 stuck high

|

instead of

|

D2 stuck low

|

U13

|

U5

|

|

H instead of @

|

D3 stuck high

|

instead of

|

D3 stuck low

|

U14

|

U5

|

|

P instead of @

|

D4 stuck high

|

instead of

|

D4 stuck low

|

U15

|

U6

|

|

(space) instead of @

|

D5 stuck high

|

instead of

|

D5 stuck low

|

U16

|

U6

|

|

instead of @

|

D6 stuck high

|

instead of

|

D6 stuck low

|

U17

|

U6

|

|

instead of @

|

D7 stuck high

|

instead of

|

D7 stuck low

|

U18

|

U6

|

Table

3 - Low RAM Flash Screens (does not display on web page, download PDF)

The second low-RAM test is

designed to identify addressing faults. The RAM tests implemented in the

original Commodore diagnostic tools wrote the same byte across the entire

address space. This makes them unable to highlight addressing related issues,

such as failed multiplexers.

The address bus testing in

Diag264 tries to be a bit smarter. It implements a more elegant test which

writes a bit pattern to a given memory address, and then writes the inversion

of this bit pattern to all the complementary addresses where the address

differs by the inversion of only one of the address bus lines.

In Diag264 we use a base

address at $00FF, so we first write $00 to the addresses in Table

4, which are $00FF plus all the complementary addresses of $00FF below $0FFF.

Then we write a value of $FF only

to $00FF, and check that all of the other addresses still contain $00. If there

is any problem decoding addresses, or there is a stuck address lines in either

in the multiplexers or the RAM’s themselves, then one or more of the addresses

above would also appear to have changed. This is a simple but powerful tool to

detect addressing problems.

Faults are reported using the

same mechanism as the data-bus test, except the background will be blue. The

number of flashes corresponds to the address line where the problem was

identified, as shown in Table 4. As before, further clues may be determined by

observing the screen contents during the screen flash cycles. Problems found in

the addressing tests often indicate failed multiplexers (74LS257) which are in

positions U7 and U8 on a C16/C116 and U9 and U10 in a Plus/4.

|

Address

|

Address

Bus

|

Flashes

on failure

|

|

$007F

|

0000 0111

1111

|

8

|

|

$00BF

|

0000 1011

1111

|

7

|

|

$00DF

|

0000 1101

1111

|

6

|

|

$00EF

|

0000 1110

1111

|

5

|

|

$00F7

|

0000 1111

0111

|

4

|

|

$00FB

|

0000 1111

1011

|

3

|

|

$00FD

|

0000 1111

1101

|

2

|

|

$00FE

|

0000 1111

1110

|

1

|

|

$00FF

|

0000 1111

1111

|

base address

|

|

$01FF

|

0001 1111

1111

|

9

|

|

$02FF

|

0010 1111

1111

|

10

|

|

$04FF

|

0100 1111

1111

|

11

|

|

$08FF

|

1000 1111

1111

|

12

|

Table

4 - Address Bus Flash Codes

The final low-ram test is a

device test, which writes a sequence of 20 test bytes across the address,

followed by a pseudo random pattern. The bytes are:

$7F, $BF, $DF, $EF, $F7, $FB,

$FD, $FE, $80, $40, $20, $10, $08, $04, $02, $01, $FF, $AA, $55, $00

The screen border will cycle

through a sequence of colours as each test byte is used and, as the low-ram

area includes the screen and colour memory, you will see the contents of the

screen rapidly change. The same reporting mechanism of flashing the border is

used if an error is found during this test, with the screen background being

black. If a failure occurs at this point, the number of screen flashes will

point very strongly to the defective DRAM. The table below shows which IC is

the likely problem.

|

Flashes

|

Bit

|

Plus/4

IC

|

C16/C116

IC

|

|

1

|

D0

|

U11

|

U5

|

|

2

|

D1

|

U12

|

U5

|

|

3

|

D2

|

U13

|

U5

|

|

4

|

D3

|

U14

|

U5

|

|

5

|

D4

|

U15

|

U6

|

|

6

|

D5

|

U16

|

U6

|

|

7

|

D6

|

U17

|

U6

|

|

8

|

D7

|

U18

|

U6

|

Table 5

- Possible Failed RAM Chips

Once in the flash sequence,

problems with particular devices will often be visually obvious as the screen contents

cycle between $00 and $FF. For example, if on a Plus/4 U15 has failed leaving

bit 4 stuck high, instead of seeing alternating ‘@’ and ‘’ symbols, you would see ‘P’

(hex value $10) and ‘’.

Once the low RAM tests have

completed, Diag264 knows that the zero-page and stack are now functioning

correctly, so the stack is initialised and the TED registers set up as they

would be on normal machine start-up. As we now know the screen RAM is

functional, we can revert to a more human friendly form of communication before

moving on to the more comprehensive tests.

Screen Layout

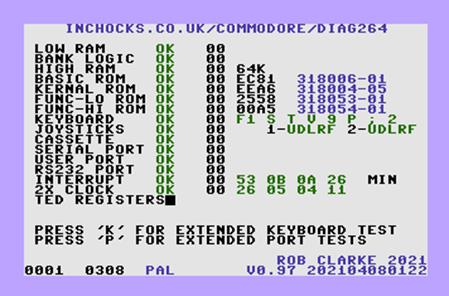

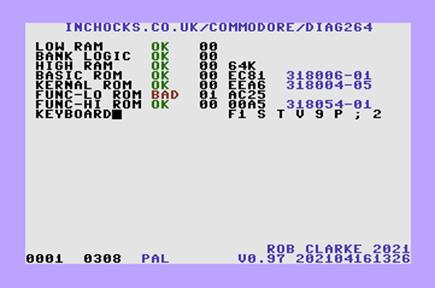

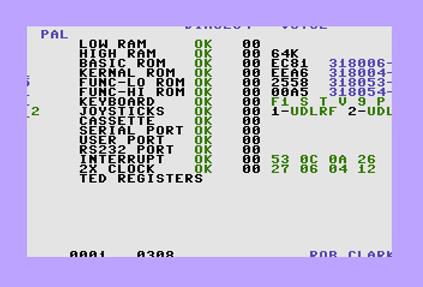

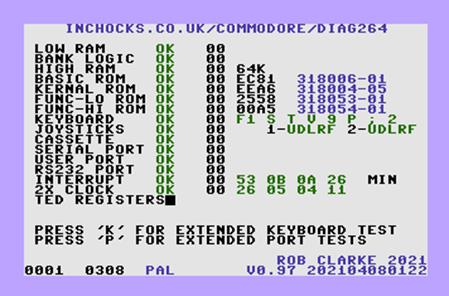

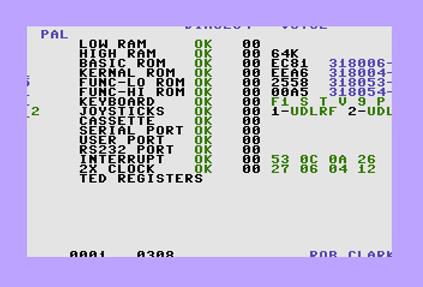

Now is a good time to explain the general layout of the

screen, most of which is self-explanatory. Look at the screenshot of a

completed test cycle in Screenshot 2. On the top line is the Diag264 web page

link. On the bottom line, from left to right, is the current cycle number in

hexadecimal, the current random number seed used in the RAM tests, and the

video mode. In the bottom right corner is my name and the year, and below is

the release version and build number. The build number is the timestamp of when

the binary was compiled, in the format YYYYMMDDHHMM.

Down the left side is the name of current test in progress,

followed by the status of the completed tests, which would be OK, FAIL, or

SKIP. The next numeric column is the total number of failures for this test

since the tests started. If the diagnostic is left on continuous loop, this is

useful for spotting intermittent failures. To the right is information specific

to the test, which is covered in the explanations below. As each test runs, the

cursor will flash to the immediate right of the test name. The area below the

list of tests may contain various other additional information, depending on

the current test.

Screenshot

2 - Screen Layout

Bank logic Test

The Bank Logic test serves two

purposes; to test the “Enable RAM” virtual TED register at $FF3E, and then to

test the ROM selection logic implemented by writing to address locations

$FDD0-$FDDF. The first test sets the $FF3E register then checks to see if RAM

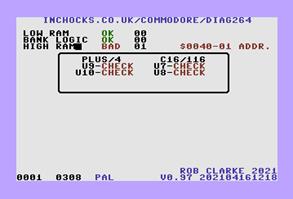

is visible in the kernal area. If this fails, you will see something like Screenshot 3 – Enable RAM Failure, with a brief description in a message box.

Problems with this register would usually indicate a problem with the TED chip.

The second test compares a

sequence of bytes in various ROM configurations, ensuring that the expected

bytes are visible as the low-ROM and high-ROM configurations are switched. This

test can identify three possible failure conditions. Firstly that the low-ROM

banking is not switching as expected, then that the high-ROM banking is not

switching, and finally that the kernal does not always remain visible in the

area from $FC00 to $FCFF. In the 264 architecture, the kernal banking routines

reside in this area and the PLA has logic to ensure that that the kernal is

always visible, irrespective of which high-ROM bank is selected. In Screenshot 4 – ROM Banking Failure all three messages are shown as an example, but

only those detected will be displayed during normal operation.

The banking logic is controlled

by the PLA and three supporting logic chips. The locations are shown below in Table 6 - Banking Logic Chips. If Diag264 does highlight an issue with the ROM

banking logic, any of the below chips could potentially be at fault.

|

Chip

|

Plus/4

|

C

16

|

C116

|

|

PLA 251641-02

|

U19

|

U16

|

U101

|

|

74LS139

|

U20

|

U14

|

U103

|

|

74LS175

|

U21

|

U15

|

U105

|

|

74LS27 / 74LS02

|

U22

|

U12

|

U104

|

Table

6 - Banking Logic Chips

The message box will remain visible for approximately 5

seconds before being cleared and moving onto the next test, however the summary

message to the right of the test status will remain visible.

High Ram Test

The high RAM test performs a

similar sequence of tests to the low RAM tests, but on the memory area from

$1000 to the upper end of installed RAM, which could be $3FFF, $7FFF or $FFFF,

depending on the model under test. The test first identifies the amount of

installed RAM by writing a sequence of bytes to $30 and checking to see if they

are mirrored at $4030 or $8030. The amount of installed memory is displayed when

the test completes.

On a 64K system we also need to test the

RAM that resides beneath the ROM’s. To do this, the test code is copied to

$0200 and the RAM made visible by writing to the TED pseudo register at $FF3F.

As it’s not possible to access the RAM beneath the I/O areas, memory is then

tested up to $FCFF and then from $FF20 to $FFFF, skipping locations $FF3E and

$FF3F.

In order to speed the tests up,

the screen is blanked, allowing us to make use of the clock doubling feature of

the TED architecture. On a 64K system they will take approximately 20 seconds

to complete and the screen colour will cycle as the test values change.

Two types of error can be

reported, either an addressing or a device error. The addressing error occurs

when performing the same type of address testing as described in the low RAM

tests, only this time testing the complete address range. As shown in Screenshot 5 - RAM Address Failure the address where the error occurred will be

displayed, as well as an “exclusive or” between the written and expected value.

Additionally, a message box will be displayed for a few seconds highlighting

the chips possibly at fault, which for addressing errors could be the 74LS257

multiplexers. Due to the limitations of testing only via software, this cannot

be definitive, and addressing errors can also come from physical issues on the

PCB and the CPU itself.

A device error occurs when a

value read does not match what was written to a given memory location. As well

as the byte pattern tests as described in the low RAM tests, the high RAM device

test also writes a sequence of pseudo random numbers across the address space

to try and catch subtle pattern memory issues that otherwise would not show up.

If Diag264 is left running, each iteration of the high RAM test will start with

a new seed value, ensuring the maximum possible exercising of the RAM.

As shown in Screenshot

6 – RAM Device Failure the address where the error occurred is again displayed,

as well as an “exclusive or” between the written and expected value. Also, a

message box will be displayed which will attempt to highlight which RAM chip is

likely at fault. The message box lists the chips for the Plus/4, C16, and C116

and does not attempt to guess which machine the tests are running on.

ROM Tests

The ROM tests perform checksums on any installed ROMS,

including those in the Function High and Low sockets in a Plus/4, which would usually

be the 3+1 software. The checksum routine is copied to $0200 in RAM to allow

the different ROM’s to be switched in. The Low ROM area is summed from $8000 -

$BFFF and High ROM from $C000 - $FFFF, with the exception of $FD00 – $FF1F for

the I/O area, the two bytes at $FF3E and $FF3F which are the virtual TED

registers, and for high ROMs other than the kernal, the area from $FC00 - $FCFF

is also skipped as the 264 architecture always exposes the default kernal in

this area to allow the bank switching and interrupt routines to always be

visible.

Each ROM is check summed three times using a cyclic redundancy

algorithm. If an inconsistent value is read, it is assumed no rom is present

and the message ‘SKIP’ is displayed. If SKIP is seen when a ROM is known to be

present, this should be considered a failure. If the checksum of the ROM is

recognised, the part number and revision is displayed. Any other computed

checksum will result in a ‘FAIL’. An example can be seen in Screenshot

7 - ROM Checksum Failure which shows a problem with the ROM in the Function Low

socket.

All known official ROM’s are recognised, along with beta

versions, those with modified Hungarian characters sets, and the kernal

modified by Andrew Challis, to support his 6510 CPU replacement. If the ROM is identified,

it will display the text in Table 7 - Diag264 recognized ROM's below, which in

the case of officially released ROM’s, will be the Commodore part number.

|

Description

|

Checksum

|

Diag 264 Display

|

|

Basic ROM Beta 0119 (19th

January 1984)

|

$F885

|

BETA 0119

|

|

Basic ROM Beta 0203 (3rd

February 1984)

|

$23D5

|

BETA 0203

|

|

Basic ROM Beta 0217 (17th

February 1984)

|

$5031

|

BETA 0217

|

|

Basic ROM Release version

|

$EC81

|

318006-01

|

|

Kernal ROM Beta 0119 (19th

January 1984)

|

$1D45

|

BETA 0119

|

|

Kernal ROM Beta 0203 (3rd

February 1984)

|

$0355

|

BETA 0203

|

|

Kernal ROM Beta 0217 (17th

February 1984)

|

$D17A

|

BETA 0217

|

|

Kernal ROM Beta 0316 (16th

March 1984)

|

$424E

|

BETA 0316

|

|

PAL kernal Revision 1 (EPROM only)

|

$33F0

|

318004-01

|

|

PAL kernal Revision 3

|

$1FC9

|

318004-03

|

|

PAL kernal Revision 4

|

$010D

|

318004-04

|

|

PAL kernal Revision 5

|

$EEA6

|

318004-05

|

|

NTSC kernal Revision 4

|

$5FAD

|

318005-04

|

|

NTSC kernal Revision 5

|

$5CD4

|

318005-05

|

|

Hungarian PAL kernal Revision 1

|

$CAE8

|

318030-01

|

|

Hungarian PAL kernal Revision 2

|

$F3DA

|

318030-02

|

|

PAL 6510 CPU replacement (Rev 5)

|

$E02B

|

6510 PAL V1

|

|

NTSC 6510 CPU replacement (Rev 5)

|

$5259

|

6510 NTSC V1

|

|

3+1 Function Low

|

$2558

|

318053-01

|

|

3+1 Function High

|

$00A5

|

318054-01

|

|

Micro Illustrator

|

$36C2

|

MICRO ILLUS.

|

|

Diag264

|

Varies

|

DIAG264

|

Table

7 - Diag264 recognized ROM's

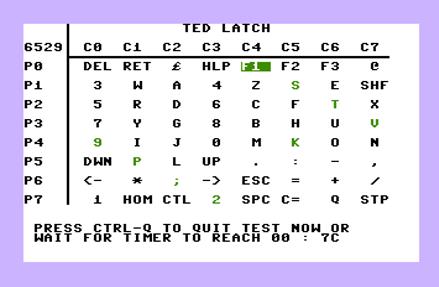

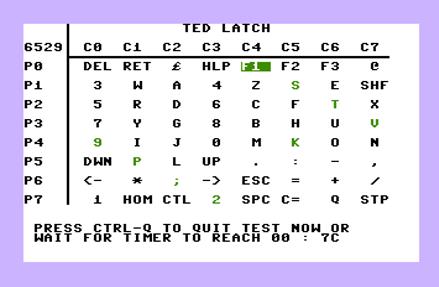

Keyboard Test

The keyboard test checks two aspects of the keyboard operation,

the 6529 single port interface and the keyboard latch on the TED chip. It does

not perform an exhaustive check on the keyboard matrix, as this can be done in

the advanced keyboard tests discussed later. The test can be carried out

manually or by using the keyboard loop-back plugs for unattended testing.

The test first checks to see if the shift-lock is held down.

If so, the remainder of this test, as well as the joystick test, is skipped,

avoiding unnecessary delays waiting for keys that will never be pressed if the loop-back

plugs are not in place. If not, the 6529 keyport is tested to see if it can

hold a value by writing to the port and comparing with the values that are read

back. If any problems are detected with the keyport, the message “6529 KEYPORT

BAD” is shown when the keyboard test completes.

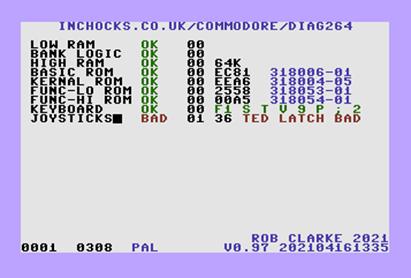

The keyboard port is then cleared (all bits set high) and the

TED keyboard latch sampled. If the latch contains anything other than $FF, this

indicates a possible keyboard problem. At this point a string of 8 keys to be

pressed is displayed on the screen, as seen in Screenshot 8.

Screenshot 8 – Keyboard Test

The test will then pull each of the lines low on the keyport

in turn, keeping each one low for approximately 2 seconds. The leftmost black key

is the one that should be pressed if a keyboard is attached and also

corresponds to the loop-backs on the keyboard connector if that is being used.

The keys and loop-backs have been chosen so that each line on the keyport pulls

a different bit of the TED latch low. If the corresponding bit of the latch

does not go low within two seconds, that port/latch combination is deemed to

have failed, the key is colour red, and the test moves on to the next key.

On success, the key will be coloured green and an additional

test will be done by clearing the port and re-reading the latch register after

a short delay. If the same value cannot be read from the latch it indicates a

problem with the latch being able to hold the value correctly, a common partial

failure of the TED. In this instance the message “TED LATCH BAD” will be

displayed after the joystick test has completed! You can see in Screenshot 8 that the first two keys were successfully detected, 3 and 4 were not,

and the remaining keys are currently being waited for. If a loop-back is being

used the test will complete very quickly if successful.

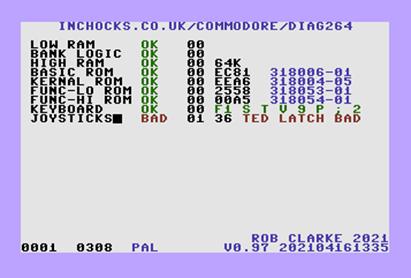

Joystick Test

The joystick test operates much in the same way as the

keyboard test, except that instead of a list of keys, a list of possible

directions for the two joystick ports is displayed. They will initially be

displayed in black text, which turn green as each direction is detected. The

test does not require the joystick to be actuated in any particular order, and will

be flagged as complete once every direction and fire button has been detected.

If directions are still outstanding after approximately 12 seconds, the test

will be flagged as a fail.

With a suitable loop-back connected, the test will complete almost

instantly. Without a loop-back, the only way to get this to successfully

complete is to have a joystick connected to both of the ports. If you suspect

one of the joystick port has issues but you only have a single joystick, you

should start the test with the joystick on port one, determine that it works or

not, then power off the machine and swap the joystick to the other port.

Although there is some electronic protection on the joystick ports, you

should never swap joysticks over with the power on.

As with the keyboard test, the TED latch is also tested to

determine that it can hold a value. If a latch problem is detected in either

the joystick test or the preceding keyboard test, the message “TED LATCH BAD”

will appear after the test completes. See Screenshot 9.

If a joystick loop-back is not available, activating the shift

lock before the test starts will cause the joystick test to be skipped.

Screenshot

9 - Failed TED Latch

Cassette test

The cassette interface on the 264 series is implemented using

P4, P1, and P3 of the 7501/8501 CPU for read, write, and motor control

respectively. On a Plus/4 the cassette sense is implemented by port bit P2 on

the user port 6529. There is no 6529 on the C16, C116 or C232 but the

equivalent cassette sense operation is mirrored using a tri-state buffer to

drive D2 to the state of the sense line when reading from $FD10.

If the cassette test fails at any point, a status byte will be

shown to the right of the cycle count which will indicate during which step of

the test it failed. The steps in the test are as follows:

01. Start with write low (P1)

and check read (P4) is high.

02. Hold write high and check read

is low.

03. Hold write low and check

read is high again.

04. With the motor off, check if

P7 in unaffected

05. Check P2 of 6529 at $FD10 is

low

06. Turn cassette motor on (P3

low), and check P3 remains low

07. Check P2 of 6529 at $FD10 is

now high.

All of the CPU output ports are inverted by a 7406 at U6 on a

Plus/4 and U9 on a C16/C116. Assuming the loop-back is installed correctly, any

failure in steps 1-6 strongly indicates that either the CPU or the 7406 is

faulty. If a failure occurs at step 7, it implies the cassette sense circuit is

at fault or, more likely, that the circuitry that provide power to the cassette

motor is at fault.

Further diagnosis of the CPU’s I/O ports can be done using the

Advanced Port Testing feature described later.

Serial test

The IEC serial port is internally looped back, with the

exception of the ATN line, which is looped back to CLK in in the connector. As

with the cassette test, a status byte will be shown to the right of the cycle

count which will indicate exactly which step of the test failed. The steps in

the test are as follows:

01. Start with DATA out (P0),

CLK out (P1) and ATN (P2) low and check DATA in (P7) and CLK in (P6) are high.

02. Hold DATA out high and check

DATA in is low.

03. Hold DATA out low and check

DATA in is high again.

04. Hold CLK out high and check

CLK in is low.

05. Hold CLK out low and check

CLK in is high again.

06. Hold ATN out high and check

CLK in is low.

07. Hold ATN out low and check

CLK in is high again.

The serial port shares much of the circuitry with the

cassette, so any problems with this test strongly indicate an issue with the

CPU ports or the 7406 inverter. Again, further diagnosis of the CPU’s I/O ports

can be done using the Advanced Port Testing feature described later.

User Port Test

The user port is only present on the Plus/4 and contains two

interfaces, the 6529 single port interface and the 6551 ACIA RS232 interface. This

test exercises both to determine correct operation, starting with the 6529

port.

After setting all port bits high (inactive), the port is read

over a period of time to ensure the value is stable. This is a best endeavour

to ensure the port is present on the machine being tested, such as a C16, as

the data lines usually float with random values if not. The test will say

‘SKIP’ if it can’t be found. If you know the port to be present, this should be

read as a fail.

The individual data lines of the port are activated in

sequence to ensure they pull the corresponding looped back data line low (see Figure 4) if not, the test will fail. In this instance, the status byte will contain

the hexadecimal representation of the failed port bits. The Advanced Port

Testing also allows you to directly manipulate the state of the port bits for

further analysis.

RS232 Port test

The ACIA is rather more complex to test as the communication

is interrupt driven. First an interrupt handler is set up in the low memory

error to catch the communication related interrupts and then the port is

configured for 8-bit words, 1 stop bit, and 2400 baud. If this value cannot be

read back from the control register, the ACIA port is assumed not to be present

and skipped. If any of the following steps fail, the step will be indicated in

the status byte.

01. RTS and DTR

are cleared. DSR is checked to see if it is set.

02. DCD is

checked to see if it is set.

03. Interrupts

are enabled and DTR is set ready. After a short delay, check that an interrupt

has occurred and that DCD has been cleared.

04. RTS is set

ready. After a short delay, check that an interrupt has occurred and that DSR

has been cleared.

Now a sequence of 192 test bytes is set up and transmitted

using the ACIA. All the communication is interrupt based, interrupts being

generated when the receive register (all 1 byte of it) is full and when the

send register is empty. The location for the received message is set up to be

about ľ of the way down the screen, so if the message is received correctly,

you should see something like Screenshot 10.

Screenshot

10 - RS232 Test

The test waits approximately 2.5 seconds for the message to be

received before checking the following conditions have been met.

05. Check that ‘bytes to send’

is now zero.

06. Check that ‘bytes received’

is now 192.

07. Check no overflow errors

occurred.

08. Check no framing errors

occurred.

09. Check no parity errors

occurred.

10. Check the contents of the

receive buffer match the send buffer

Interrupt & 2X Clock Tests

The interrupt tests check that the interrupt sources on the

TED chip are all functioning correctly. The TED has 4 usable interrupt sources;

3 timers and the raster interrupt. These are initialised to a specific

pre-condition and then allowed to run for approximately half a second, counting

the number of interrupts that occurred. If this number falls outside of the

boundaries shown below, the TED may be at fault.

The number of triggered interrupts during the period is

affected by the video standard of the machine under test (different number of

lines to render) as well as the presence of an ACIA on the system (causes more

interrupts).

The test is performed twice, the first time with the TED

forced into single clock mode and the second time with the screen blanked, thus

running at twice the speed. The interrupt sources and the boundaries currently

defined for both single and double clock operation are seen in Table 8 - Interrupt Sources and Boundaries.

|

|

Single Clock

|

Double Clock

|

|

Interrupt Source

|

Lower Bound

|

Upper Bound

|

Lower Bound

|

Upper Bound

|

|

Timer 1 with a

reload value of $2000

|

$53

|

$56

|

$26

|

$26

|

|

Timer 2,

initialised with $0100

|

$0B

|

$0B

|

$05

|

$05

|

|

Timer 3,

initialised with $FF00

|

$0A

|

$0A

|

$04

|

$04

|

|

Raster

Interrupts at scan line 204

|

$26

|

$2E

|

$11

|

$14

|

Table

8 - Interrupt Sources and Boundaries

Each count will be displayed as it completes; in green if

within the boundaries defined above, otherwise red. An example of the output

for a successfully completed test is shown in Screenshot 2, earlier in the

document.

Upon completion of all tests, the number of detected

interrupts will cycle between the minimum and maximum values while Diag264

pauses at the end of each cycle. If any of the counts do vary, they will flash

blue.

TED Register Tests

The final sequence of tests attempts to test as many of the

TED registers as can reasonably be achieved in a short space of time. Some of

the registers have already been tested prior to this section, for example the

screen blanking, clock doubling and timers. For most of the remaining registers

it is not possible for the software to determine an ‘OK’ or ‘FAIL’ state so it

relies on the observer to make that decision after comparing the results to

this document.

A sequence of three screens is displayed, and the observer

should be on the lookout for deviations from what is described and shown below.

A musical scale is played for the duration of each screen using one of the

three voices for each of the screens.

Colour Palette

This screen plays a scale on voice 1

and displays a cycling colour palette. It doesn’t really do much more than show

off the TED’s colour palette.

Screenshot 11

- Colour Palette

TED Graphic Modes

The second screen has much more going on and is designed to

show the available graphics modes on a single screen using raster interrupts to

change the mode between sections. You should check carefully that what is shown

on the screen matches Screenshot 12 - TED Graphics Modes. The modes displayed

are shown alongside the screenshot. There should be no observable flickering or

other artefacts on the screen.

The top three sections show the three different text modes.

Each section shows four rows of characters with tile values of 0 – 39, 64 –

103, 128 – 167 and 192 – 231 respectively. The attribute (colour) values are

set to the same value.

The first, with the dark blue border is the default Hi-Res

text mode. Although not seen in the static picture, the third and fourth rows

will be flashing. The second, with the black background, shows multicolour

mode, which is not really suited to the inbuilt character set but should

nevertheless be noticeable on characters 8 – 15 and 24 – 31. The third text

mode, with the yellow background, shows the rarely used extended background

mode, where the first 64 characters are rendered on a different coloured

background depending on the value of bits 6 and 7 of the tile value.

The bottom two sections highlight the bitmap graphics modes,

Hi-Res and multicolour, with respective green and red borders. The top should

show a grid of white lines and the bottom a grid of alternating vertical blue

and red lines with green horizontal lines.

|

Screenshot 12 - TED Graphics Modes

|

Top Border

|

|

Hi-Res Text

|

|

Multicolour Text

|

|

Extended Background

Text

|

|

Hi-Res Bitmap

|

|

Multicolour Bitmap

|

|

Bottom Border

|

|

|

Smooth Scroll

The final TED register test demonstrates the smooth scrolling

and the 24 row, 38 column modes. The status screen is moved in a sinusoidal

wave. There should be no visible artefacts on any of the borders or any

shearing of the display. The white noise generator should be heard during this

test.

Screenshot 13

– Smooth Scroll

Test Cycle Completion

At the end of the test, the display will pause for a few

seconds before looping round and continuing from the High RAM test again.

During this time, the minimum and maximum interrupt values will be displayed,

if any. You also have the option to select from two advanced tests, pressing

‘K’ for the extended keyboard tests, and ‘P’ for the extended ports testing. If

the keyboard loop-back plug is detected, this option will not appear, as

clearly the keyboard is unavailable.

Just before starting again, a brief sample will play to test

the TED’s digital sample playing capabilities.

Extended Keyboard test

When the main tests complete, there will be a pause of a few

seconds before the cycle starts again.

The advanced keyboard tests were implemented to identify

keyboard reliability issues and to identify patterns which may cause complete

rows or columns of keys to fail, which may in turn indicate that there is a

problem with the keyboard output port or TED latch. Fundamental problems should

be detected by the man keyboard test, but this allows for an additional level

of investigation.

Displayed you will see a screen as shown in Screenshot

14 – Advanced Keyboard Testing, which shows the keyboard not as it is

physically laid out, but according to the rows and columns of the 6529 keyboard

port and TED latch. Initially, all keys will be black, showing that the key has

not yet been pressed. While each key is pressed, it will highlight in a

reversed green colour, which will revert to non-inverted, but still green, once

the key is released.

Using this, you can go through all keys ensuring that they are

responding correctly, including when used in conjunction with either shift, shift-lock,

or the Commodore key.

Screenshot

14 – Advanced Keyboard Testing

To exit the keyboard test, either press ‘Control’ and ‘Q’, or

wait for the hexadecimal countdown timer to reach 00, after which the main test

cycle will restart.

Extended Port tests

The extended port testing functionality was added to enable

more detailed investigation of the I/O ports on the CPU and, if fitted, the

6529 on the user port. Having issues with the ports can cause problems with the

cassette deck and the IEC port for disk drives and printers. As well as the CPU

itself, some of the failure points include the 7406 hex inverter and the diodes

that protect the I/O lines. During normal operation, it can be quite difficult

to investigate these without an oscilloscope as the states change very quickly,

but this tool allows you to maintain the ports in a steady state and toggle them

as required.

After the pressing ‘P’, you will see an image similar to the

one shown in Screenshot 15 – Extended Ports Testing . At the top of the screen

is the CPU with the CPU DDR (Data Direction Register) at memory location $00,

followed by the write value to the CPU port register itself at location $01,

and finally the value read back from the port register. All the values are

shown as a hexadecimal value, followed by a binary representation of the

register. For the DDR these are represented by ‘I’ and ‘O’ for Input and Output

respectively. For the written value, port bits set to input by the respective

value in the DDR are displayed as a dash ‘-‘, and ports set to output displayed

as a solid block for a high value, and a dot ‘.’ for a low value. For the read

value, the same scheme applies, again being shown as a solid block for a high

value and a dot for a low value. To the right is a summary of the use of the

CPU port on 264 computers.

Below the CPU is the 6529 SPI (Single Port Interface) at

location $FD10 which is exposed on the user port of the Plus/4. The 6529 does

not have a corresponding DDR, so just the write and read values are shown. To

the right is shown the only standard use of this port, where P2 is used for

cassette sense. On a C16, the 6529 is not present, but the ability to read P2

is still implemented using some basic TTL logic.

Screenshot

15 – Extended Ports Testing

Operation is quite simple, in that the ‘CTRL’ key is used to

rotate between the CPU DDR, the CPU port write value and the 6529 write value. The

selected port is highlighted in reversed green text. Once selected the

individual register bits are manipulated using the keys ‘0’ to ‘7’. On the DDR,

these will toggle the port bits between input and output, while on the write

values this will toggle between high and low outputs.

On the CPU port, any bits set as input via the DDR cannot be

changed. The default value for the DDR on 264 machine is $0F, meaning port bits

0 to 3 are outputs and 4 to 7 are inputs. There should not normally be any

reason to change the DDR from its default value, as once set by the kernel, it

is never changes during the normal operation of the machine and neither does

any other software change it to my knowledge.

If you have a cassette deck attached, then pressing play, fast

forward, or rewind, should cause the cassette sense bit to toggle. Toggling P3

on the CPU output will cause the motor to start and stop. With the motor

enabled, playing a tape with a program on should cause P4 to flicker rapidly.

As some of the CPU ports are internally connected, then

without the loop-back plugs installed toggling P0 should affect the input on

P7, and likewise P1 will affect P6.

If you have the loop-back plugs installed, then P3 (motor)

should toggle the sense line, and P1 (cassette write) should toggle P4

(cassette read.)

DIAG264 Version History

0.15A -

added colour to print_msg

-

made sure that keyport and latch messages are always displayed

-

fixed long standing bug with timer 3 checks

0.20A -

re-write of rom check routine

0.21A -

updated ZP usage

0.22A -

tidied low-ram test, integrated ted mode screen

0.4A -

integrated smooth scroll

-

added databus and address bus tests

-

added 128 char definitions

0.5A -

added better address bus tests and for high ram

0.6A -

added HW cursor

0.7A -

tolerance checks on interrupt counts

0.1B -

High RAM location reporting

-

fixed a raster synch issue with the interrupt counts which should improve count

stability

-

implemented NTSC compatible tests...

0.11B -

allowed skipping of KB test even if failures have occured

0.12B -

improved latch testing on KB test

0.13B -

fixed keyport bug

-

fixed setting of cassette motor if sense is on cpu-p7 so it doesn't break

serial test

-

fixed location of $FD10-D2 message

0.2B -

first Beta release!

-

relaxed interrupt tolerances based on running on NTSC machine

0.3b -

much improved address bus test

0.5b -

fixed databus test to correctly mask bits

0.6b -

Autodetect PAL/NTSC if running from cartridge (F33F - #$08 for PAL, #$48 for

NTSC)

-

Always allow KB skip

0.7b -

Fixed NTSC/PAL toggle. 'P' forces PAL and 'N' forces NTSC

-

Avoid conflict if dongle installed

0.8 -

Updated version & 2016

-

remove cpu-p7 cassette checks, messages etc

-

fixed raster detection in colour_sound_test

-

simplified colour sound test

0.9 -

Updated version & 2018

-

ROM checksums now CRC-16

-

use a single smooth scroll dataset and manipulate bits

-

various minor code optimisations

-

Doesn't trash the screen when check-summing function ROM's

-

stabilised raster splits

-

added various beta kernals

0.91 -

added extended KB test

-

fixed small bug in forcing NTSC mode

-

cart version now works in any low-rom position, including replacing func-low

-

cart_lo renamed to low_rom

-

fixed bug caused by small_delay sitting across a page boundary causing interrupt…

- …timing discrepancies

-

align interrupt handler to page boundary, again to avoid timing discrepancies

-

added pseudo random number testing to RAM

0.92 -

added advanced port testing

-

added checksum for Andy Challis' 6510 replacement kernal

-

reset interrupt sources at end of TED interrupt tests

0.93 -

beta release

-

changed keys to toggle ports to 0->7 instead of 1->8

-

Added some information to the EPT tests to describe the use of the ports

-

reset the ports at the beginning of EPT

-

show Diag264 and not FAIL if running from low-ROM socket

0.94 -

fixed bug that always sent the tests into the port testing if the KB loop-back

plug…

- …was installed

- added check to detect KB dongle and if present

don't show messages for advanced tests

0.95 -

updated to 2020

- fixed small bug which compared 3 bytes instead of

2 when comparing ROM CRC checksums.

A legacy from the old 3 byte checksum.

0.96 -

make TED mode use raster interrupts

- simplified tune playing routine

- reduce time waiting for joystick input, reduced to

#$c0

- improve error reporting on joystick test. (Alex

Korth email May 2019)

- if the latch doesn't have correct value at start,

or is unstable during reading, print

as status byte

- pop up a message box on ram failures suggesting

chip at fault

- fixed bug where using shift-lock to skip keyboard

and joystick persisted for joystick

on subsequent cycles

- moved receive buffer up a bit to make look neater

- reviewed and updated ZP usage

- added new banking logic tests for FF3E and FDD0

- added error for unexpected interrupts

- play a Homer Simpson WooHoo! sammple at the end of

each test cycle

- added exomizer decompression for sample data an

other stuff for future

- added Andy Challis NTSC kernal for 6510 adapter

- stabilise the interrupt counts by refactoring int

handler, skip false ACIA IRQ's if

not present

- display min and max interrupt counts, highlighting

differences at end of cycle

- explicitly set raster line on interrupt tests to

204, previously set by TED defaults

- updated to 2021

|

Figure 8

- Shady Cat

|

![]()